Product Description:

The Magnesium Alloy Plate is a high-performance material

specifically designed for use in automotive parts, offering an

excellent combination of strength, lightweight properties, and

thermal stability. Made from premium magnesium alloy, this plate

provides an ideal solution for manufacturers seeking to optimize

vehicle performance while reducing overall weight. The material’s

inherent characteristics make it highly suitable for applications

where durability and reliability are paramount.

One of the key features of this Magnesium Alloy Plate is its

precise thickness of 1.5mm, which strikes a perfect balance between

structural integrity and material efficiency. This thickness

ensures that the plate is robust enough to withstand mechanical

stresses encountered in automotive environments, while still

contributing to weight reduction goals critical for modern vehicle

design. The 1.5mm thickness also allows for easy fabrication and

integration into various automotive components without compromising

on performance.

Thermal expansion is a critical consideration in automotive

applications, and this Magnesium Alloy Plate excels in this regard

with a thermal expansion coefficient of 25 x 10 -6 /K. This low thermal expansion rate enables the plate to maintain

dimensional stability under varying temperature conditions,

minimizing the risk of deformation or failure during operation.

This attribute is particularly important for parts exposed to

engine heat or fluctuating environmental temperatures, ensuring

long-term reliability and safety.

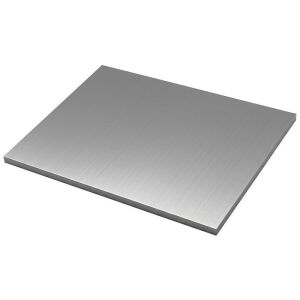

Surface treatment plays a vital role in enhancing the durability

and aesthetic appeal of metal plates. The Magnesium Alloy Plate

undergoes a meticulous polishing process that results in a smooth,

attractive finish. Polishing not only improves the visual quality

of the plate but also provides a protective layer that helps resist

corrosion and wear. This surface treatment ensures that the

Magnesium Alloy Sheet Metal maintains its performance and

appearance even after prolonged use in demanding automotive

settings.

As a Magnesium Alloy Sheet Metal, this product offers exceptional

versatility, making it suitable for a wide range of automotive

parts including structural components, engine covers, brackets, and

housings. The lightweight nature of magnesium alloy helps reduce

the overall weight of vehicles, contributing to improved fuel

efficiency and reduced emissions. Additionally, the excellent

mechanical properties of the Magnesium Alloy Sheet ensure that

parts fabricated from this material deliver superior strength and

impact resistance.

Manufacturers who choose this Magnesium Alloy Sheet will benefit

from its ease of fabrication and excellent weldability, enabling

efficient production processes and cost savings. The combination of

lightweight, strength, and thermal stability makes it an ideal

choice for cutting-edge automotive designs that prioritize both

performance and sustainability. Furthermore, the polished surface

treatment enhances the product’s appeal in visible applications,

where both functionality and aesthetics are important.

In summary, the Magnesium Alloy Plate with a thickness of 1.5mm,

polished surface treatment, and a thermal expansion coefficient of

25 x 10 -6 /K is a superior material choice for automotive parts. Its unique

blend of lightweight characteristics, thermal stability, and

polished finish makes it a standout option for manufacturers

looking to improve vehicle efficiency and durability. Whether used

as a Magnesium Alloy Sheet or Magnesium Alloy Sheet Metal, this

product guarantees consistent quality, excellent performance, and

long-lasting reliability in demanding automotive applications.

Features:

- Product Name: Magnesium Alloy Plate

- Thickness: 1.5mm

- Elongation: 10%

- Shape: Plate

- Tensile Strength: 120 MPa

- Material: High-quality Magnesium Alloy

- Ideal for use as Magnesium Tooling Plate

- Suitable for applications requiring Magnesium Sheet Metal

- Durable and lightweight Magnesium Sheet Metal solution

Technical Parameters:

| Size | 1000mm X 1000mm |

| Application | Automotive Parts |

| Surface Treatment | Polishing |

| Thickness | 1.5mm |

| Tensile Strength | 120 MPa |

| Corrosion Resistance | Excellent |

| Yield Strength | 90 MPa |

| Shape | Plate |

| Hardness | HB30 |

| Material | Magnesium Alloy |

Applications:

The Hilbo Magnesium Alloy Plate, originating from Dongguan, China,

is a premium-quality product designed to meet the rigorous demands

of various high-performance applications. With its polished silver

surface and precise dimensions of 1000mm by 1000mm, this magnesium

alloy sheet metal offers exceptional strength-to-weight ratio and

excellent corrosion resistance, making it an ideal material for

automotive parts and other industrial uses.

One of the primary application occasions for the Hilbo Magnesium

Alloy Plate is in the automotive industry. As manufacturers

increasingly seek lightweight materials to improve fuel efficiency

and reduce vehicle emissions, magnesium alloy sheet metal has

become a preferred choice for components such as engine blocks,

transmission cases, and structural parts. The polished surface

treatment not only enhances the aesthetic appeal but also improves

the durability and wear resistance of the parts fabricated from

these plates.

In addition to automotive parts, the Hilbo Magnesium Alloy Plate is

suitable for use in aerospace, electronics, and sports equipment

manufacturing. Its lightweight nature, combined with high

mechanical strength, allows for the creation of components that

require both performance and reliability. For instance, in

aerospace applications, magnesium alloy plates contribute to

overall weight reduction, which is critical for fuel savings and

enhanced flight performance.

The versatility of this magnesium alloy sheet metal also makes it

perfect for prototyping and custom fabrication projects. Whether

used in industrial machinery or consumer electronics, the 1000mm x

1000mm plate size offers ample material for cutting and shaping

into complex parts while maintaining structural integrity. The

silver polished finish ensures that the final product not only

performs well but also presents a sleek and professional look.

Overall, the Hilbo Magnesium Alloy Plate is an excellent choice for

industries that demand lightweight, durable, and

corrosion-resistant sheet metal. Its application scenarios span

automotive parts manufacturing, aerospace components, electronics

housings, and beyond. With its reliable quality and superior

surface treatment, this magnesium alloy sheet metal provides a

versatile solution for modern engineering challenges.

Customization:

Hilbo offers premium product customization services for our

Magnesium Alloy Plate, crafted with high-quality magnesium alloy

material. Originating from Dongguan, China, our Magnesium Tooling

Plate is designed specifically for automotive parts applications,

ensuring excellent corrosion resistance and durability. The

silver-colored Magnesium Alloy Sheet is shaped into precise plates

to meet your specific requirements, providing superior performance

and reliability. Trust Hilbo to deliver customized Magnesium

Tooling Plate solutions tailored to your needs.

Support and Services:

Our Magnesium Alloy Plate product is backed by comprehensive

technical support and services to ensure optimal performance and

customer satisfaction. We provide detailed product specifications,

usage guidelines, and maintenance instructions to help you maximize

the benefits of our magnesium alloy plates.

Our technical support team is available to assist with any

inquiries related to material properties, processing techniques,

and application recommendations. We offer customization options to

meet specific project requirements and provide expert advice on

welding, machining, and corrosion resistance.

Additionally, we conduct quality assurance testing and provide

certification documentation to guarantee the reliability and

consistency of our magnesium alloy plates. Our services also

include after-sales support to address any issues and ensure

seamless integration of our products into your operations.

For technical assistance, please refer to our product manuals and

online resources, which include FAQs, troubleshooting guides, and

application case studies to support your project needs.

Packing and Shipping:

Our Magnesium Alloy Plates are carefully packaged to ensure maximum

protection during transit. Each plate is individually wrapped with

anti-corrosion paper and securely placed in a sturdy wooden crate

or reinforced cardboard box, depending on the order size.

Protective padding materials are added to prevent any movement or

damage.

For shipping, we offer multiple options including sea freight, air

freight, and express delivery to accommodate your timeline and

budget. All shipments are handled by experienced logistics partners

to guarantee timely and safe delivery. Tracking information will be

provided once your order is dispatched.

We comply with all international shipping regulations for hazardous

materials, ensuring that our Magnesium Alloy Plates reach you

safely and without delay. Custom packaging solutions are available

upon request to meet specific requirements.

FAQ:

Q1: What is the brand name of the Magnesium Alloy Plate?

A1: The Magnesium Alloy Plate is manufactured under the brand name

Hilbo.

Q2: Where is the Magnesium Alloy Plate produced?

A2: The Magnesium Alloy Plate is produced in Dongguan, China.

Q3: What are the typical applications of Hilbo Magnesium Alloy

Plates?

A3: Hilbo Magnesium Alloy Plates are commonly used in aerospace,

automotive, electronics, and lightweight structural components due

to their high strength-to-weight ratio.

Q4: What are the advantages of using Magnesium Alloy Plates over

other metals?

A4: Magnesium Alloy Plates offer excellent strength, lightweight

properties, good corrosion resistance, and high thermal

conductivity, making them ideal for applications where weight

reduction is critical.

Q5: Can the Magnesium Alloy Plate be customized in terms of size

and thickness?

A5: Yes, Hilbo offers customization options for Magnesium Alloy

Plates to meet specific size and thickness requirements based on

customer needs.