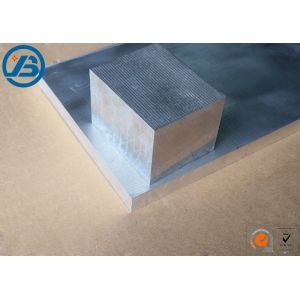

Product Description:

The Magnesium Alloy Plate is a high-quality material designed to

meet the demanding requirements of modern manufacturing,

particularly in the automotive industry. This product is

characterized by its remarkable combination of lightweight

properties, mechanical strength, and exceptional corrosion

resistance, making it an ideal choice for a wide range of

automotive applications. The plate is precisely fabricated to a

size of 1000mm by 1000mm, providing a versatile and convenient

dimension for various production needs.

One of the standout features of this Magnesium Alloy Plate is its

excellent corrosion resistance. Unlike many other metals and alloys

that are prone to degradation when exposed to harsh environmental

conditions, this magnesium alloy maintains its integrity and

appearance over time. This resistance to corrosion ensures

longevity and durability, which are critical factors for components

used in automotive parts that may be subjected to moisture, salt,

and other corrosive elements during their service life.

The product is supplied in the form of a plate, offering a flat,

stable surface ideal for manufacturing processes that require

uniform thickness and strength. This shape allows for easy

handling, cutting, and forming, making it suitable for various

fabrication methods. Whether the application involves stamping,

machining, or welding, the Magnesium Alloy Plate provides a

reliable base material that responds well to different processing

techniques.

In terms of mechanical performance, this Magnesium Alloy Plate

boasts a yield strength of 90 MPa. This level of strength strikes

an excellent balance between being lightweight and durable, which

is especially beneficial in automotive manufacturing where reducing

weight without compromising safety and performance is a key

objective. The yield strength ensures that parts made from this

alloy can withstand significant stress and strain before deforming,

contributing to the overall safety and efficiency of vehicles.

When it comes to applications, the Magnesium Alloy Plate is

predominantly used in the production of automotive parts. Its light

weight helps reduce the overall mass of vehicles, leading to

improved fuel efficiency and reduced emissions. Components such as

brackets, housings, and structural elements benefit from the

material’s strength-to-weight ratio and excellent corrosion

resistance. The versatility of this plate also allows it to be used

in other sectors where similar performance attributes are required,

but its primary focus remains on the automotive market.

Additionally, this product is often referred to as Magnesium Alloy

Sheet Metal or Magnesium Alloy Sheet, highlighting its role as a

fundamental material in sheet metal fabrication processes. These

terms emphasize the product’s flat and thin characteristics, which

are essential for creating precise and consistent automotive parts.

The Magnesium Alloy Sheet Metal designation also underscores the

product’s suitability for high-volume manufacturing environments

where uniformity and quality control are paramount.

In conclusion, the Magnesium Alloy Plate combines excellent

corrosion resistance, a practical plate shape, a convenient size of

1000mm X 1000mm, and a strong yield strength of 90 MPa to provide a

superior material solution for automotive parts manufacturing. Its

properties make it an indispensable component in producing lighter,

more durable, and environmentally friendly vehicles. Whether

referred to as Magnesium Alloy Sheet Metal or Magnesium Alloy

Sheet, this product stands out as a reliable and efficient choice

for engineers and manufacturers aiming to optimize performance and

longevity in automotive design.

Features:

- Product Name: Magnesium Alloy Plate

- Also known as Magnesium Tooling Plate and Magnesium Alloy Sheet

- Thermal Conductivity: 150 W/mK for efficient heat dissipation

- Tensile Strength: 120 MPa ensuring high mechanical performance

- Thickness: 1.5mm suitable for various applications

- Yield Strength: 90 MPa providing excellent structural integrity

- Thermal Expansion: 25 x 10 -6 /K to maintain dimensional stability under temperature changes

Technical Parameters:

| Material | Magnesium Alloy |

| Shape | Plate |

| Corrosion Resistance | Excellent |

| Hardness | HB30 |

| Thermal Conductivity | 150 W/mK |

| Thermal Expansion | 25 × 10 -6 /K |

| Elongation | 10% |

| Surface Treatment | Polishing |

| Color | Silver |

| Application | Automotive Parts |

Applications:

The Hilbo Magnesium Alloy Sheet, originating from Dongguan, China,

is a premium product designed to meet the demanding requirements of

modern industries. With a thickness of 1.5mm and a density of 1.8

g/cm³, this magnesium alloy sheet metal offers an excellent balance

of lightweight properties and structural strength. Its 10%

elongation ensures adequate flexibility, making it ideal for

various applications, especially in the automotive sector.

One of the primary application occasions for the Hilbo Magnesium

Tooling Plate is in the manufacturing of automotive parts. The

automotive industry continuously seeks materials that can reduce

vehicle weight without compromising safety or performance. The

lightweight nature of magnesium alloy sheet metal significantly

contributes to improved fuel efficiency and reduced carbon

emissions, aligning with global sustainability goals. These sheets

are often used in the production of engine components, interior

panels, and structural parts where weight reduction is critical.

In addition to automotive parts, the polished surface treatment of

the Hilbo magnesium alloy sheet makes it suitable for use in

tooling and mold-making environments. The smooth, polished surface

reduces friction and wear, enhancing the durability of tooling

plates. This makes the magnesium tooling plate an excellent choice

for precision tooling applications where high dimensional accuracy

and surface finish are paramount.

Moreover, the magnesium alloy sheet metal finds usage in aerospace

and electronics industries, where weight savings and mechanical

performance are equally important. In aerospace, the 1.5mm

thickness and 10% elongation allow for the fabrication of

lightweight structural components that can withstand operational

stresses. In electronics, the material's excellent thermal

conductivity and lightweight nature make it suitable for heat sinks

and casings.

Overall, the Hilbo Magnesium Alloy Sheet from Dongguan, China, is a

versatile material that excels in scenarios requiring lightweight,

strength, and durability. Its application in automotive parts,

tooling plates, and other high-performance industries highlights

its value. The polished surface treatment further enhances its

functionality, making it a preferred choice for manufacturers

aiming to optimize performance and efficiency.

Customization:

Hilbo offers premium Magnesium Alloy Plate customization services,

originating from Dongguan, China. Our Magnesium Alloy Sheet

products are crafted from high-quality Magnesium Alloy material,

ensuring excellent performance and durability. The standard size of

our Magnesium Alloy Sheet is 1000mm x 1000mm, making it suitable

for a wide range of industrial applications.

Our Magnesium Alloy Plate features a thermal expansion coefficient

of 25 x 10 -6 /K, providing stability under varying temperature conditions. With

a hardness rating of HB30 and a density of 1.8 g/cm 3 , our Magnesium Alloy Sheet is designed to meet your specific

requirements for strength and lightweight properties.

We specialize in customizing the Magnesium Alloy Plate to your

precise specifications, ensuring that each product meets your

unique needs. Trust Hilbo for reliable, high-quality Magnesium

Alloy Sheet solutions that combine advanced material properties

with expert craftsmanship.

Support and Services:

Our Magnesium Alloy Plate product comes with comprehensive

technical support and services to ensure optimal performance and

customer satisfaction. We provide detailed product specifications,

usage guidelines, and maintenance instructions to help you achieve

the best results.

Our technical support team is available to assist with any

inquiries related to material properties, processing methods, and

application techniques. We offer expert advice on machining,

welding, and surface treatment to enhance the durability and

functionality of the magnesium alloy plates.

In addition, we provide customized solutions to meet specific

project requirements, including tailored alloy compositions and

dimensions. Our quality assurance services include rigorous testing

and inspection to guarantee that each plate meets industry

standards and customer expectations.

For ongoing support, we offer training sessions and technical

workshops aimed at improving handling and fabrication skills. Our

commitment is to deliver reliable products backed by responsive and

knowledgeable service throughout the product lifecycle.

Packing and Shipping:

Each Magnesium Alloy Plate is carefully packaged to ensure maximum

protection during transit. The plates are first wrapped in

anti-corrosion paper to prevent oxidation and surface damage. They

are then placed in sturdy, reinforced cardboard boxes with foam

padding to absorb shocks and vibrations.

For bulk orders, the plates are stacked on wooden pallets and

securely strapped to prevent movement. The pallets are further

shrink-wrapped to protect against moisture and dust.

All packages are clearly labeled with handling instructions and

product details to facilitate safe and efficient shipping.

We offer various shipping options including standard ground,

expedited air freight, and international shipping, ensuring timely

delivery to your specified location.

FAQ:

Q1: What is the brand name of this magnesium alloy plate?

A1: The magnesium alloy plate is manufactured under the brand name

Hilbo.

Q2: Where is the Hilbo magnesium alloy plate produced?

A2: The Hilbo magnesium alloy plate is produced in Dongguan, China.

Q3: What are the common applications of the Hilbo magnesium alloy

plate?

A3: Hilbo magnesium alloy plates are commonly used in automotive,

aerospace, electronics, and construction industries due to their

lightweight and high strength properties.

Q4: What are the key benefits of using a magnesium alloy plate from

Hilbo?

A4: The Hilbo magnesium alloy plate offers excellent

strength-to-weight ratio, corrosion resistance, and good thermal

conductivity, making it ideal for various industrial applications.

Q5: Can the Hilbo magnesium alloy plate be customized to specific

sizes and thicknesses?

A5: Yes, the Hilbo magnesium alloy plate can be customized

according to customer requirements in terms of size, thickness, and

surface finish.